A Legacy of Japanese Craftsmanship

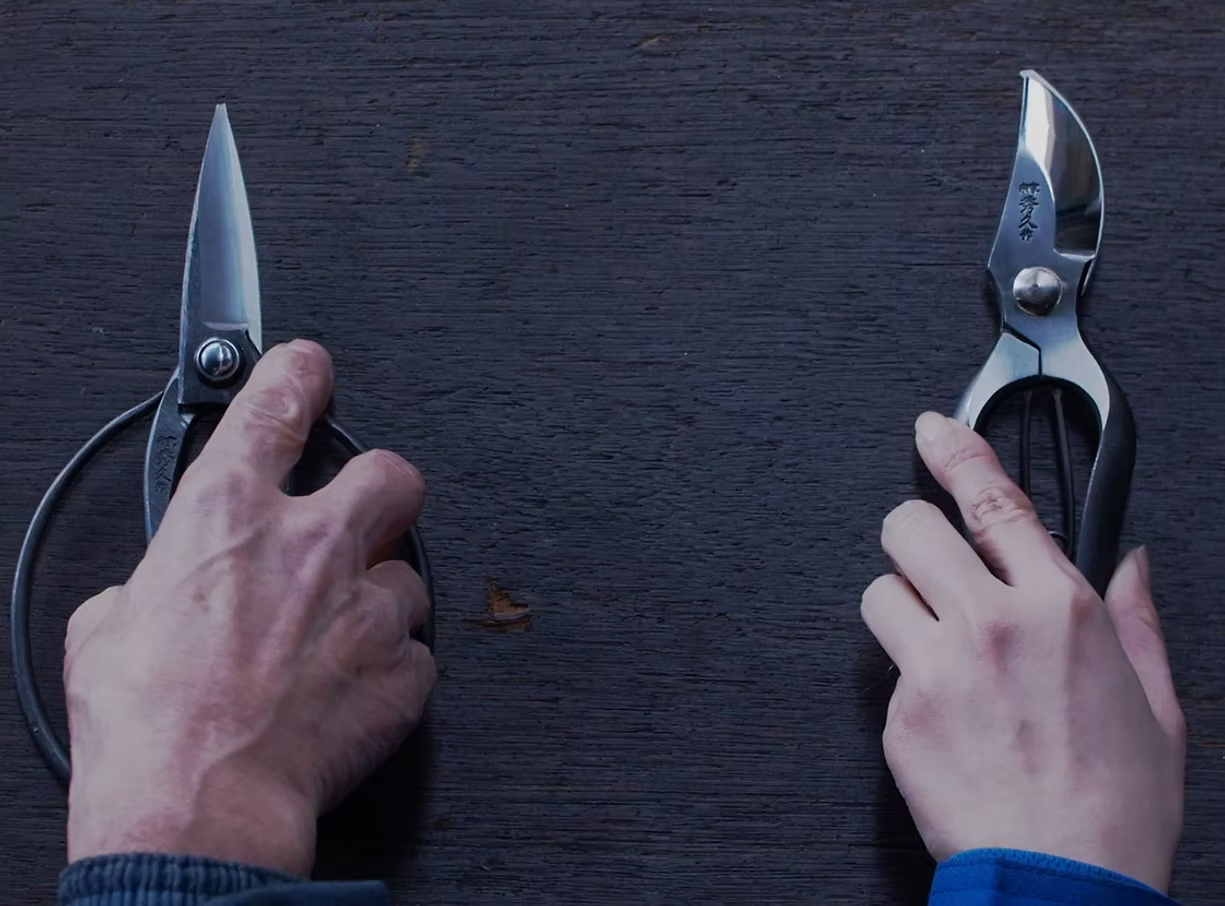

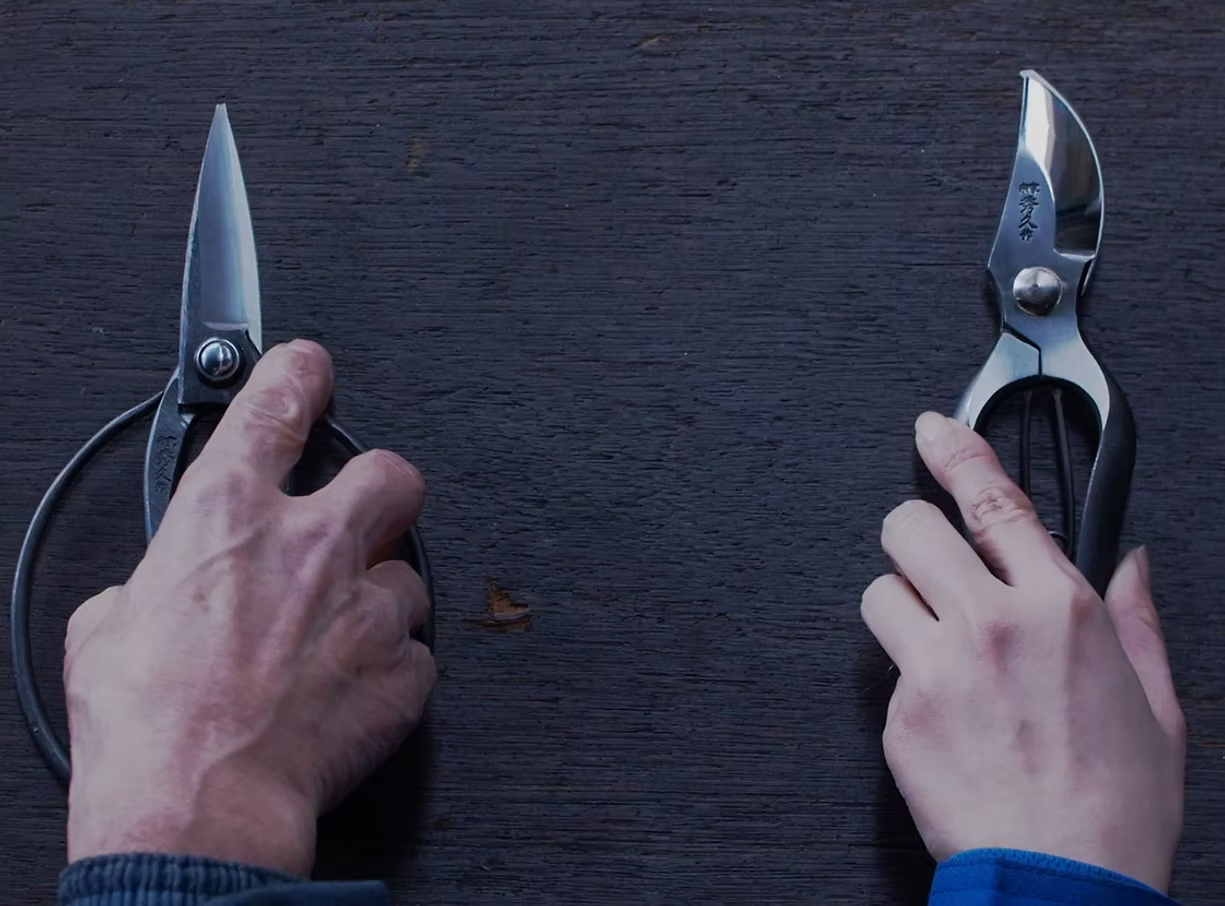

Toyama Hamono stands out in gardening tools, combining centuries-old Japanese blacksmithing with modern sustainability and innovation. Our handcrafted shears, pruning tools, and bonsai scissors are both beautiful and highly functional.

A Tradition of Excellence: More Than Just Tools

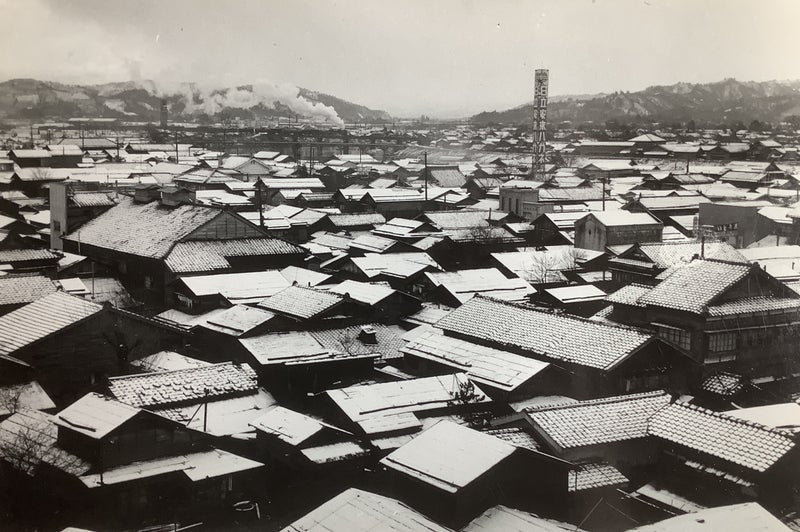

Toyama Hamono embodies Japanese heritage and craftsmanship. Since 1861, we have handcrafted gardening shears, pruning tools, and bonsai scissors in Sanjo, Niigata—a city with a rich metalworking tradition. Our founder, Toyama Ryumatsu, came to Sanjo from the Wakasa Province, inspiring our “Wakasa-ya” trade name. In Sanjo, bladesmithing is a treasured legacy, and we honor this by preserving time-honored techniques while embracing modern innovation. This balance gives our tools exceptional function, character, and soul.

Five Generations of Craftsmanship: A Family's Dedication

Toyama Hamono's story is woven through five generations of dedicated artisans. Our vision was simple: create the finest cutting tools using the best materials and techniques.

Foundation - The Seeds of Craftsmanship

First Generation (Toyama Ryumatsu - 1861 onwards)

Founded in 1861 in Sanjo, Niigata, Toyama Ryumatsu used his samurai heritage to craft wooden-handled hedge shears (Ki-basami) at local request. He initially forged them from salvaged warship rivets and later refined his skills by studying pruning shear manufacturing in Tokyo.

Innovation & Diversification

Second Generation (Toyama Tomijiro - c. 1880s onwards)

The second generation, Toyama Tomijiro, expanded the product line to include metal-cutting shears. This era saw advanced tempering and steel-forging, enhancing tool durability and lifespan.

Refinement & Community Leadership

Third Generation (Toyama Hidekichi - c. 1906 onwards)

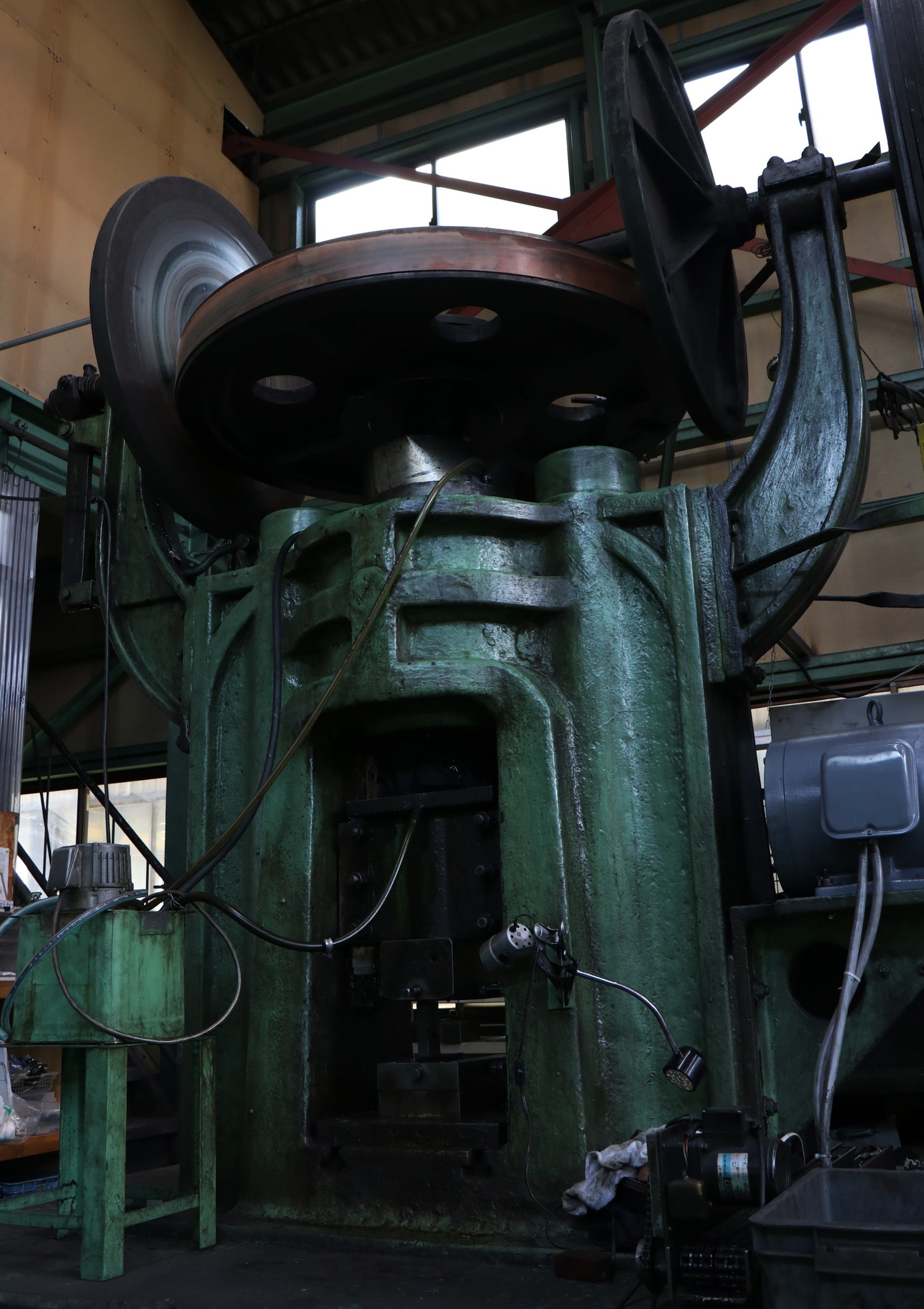

Toyama Hideyoshi founded "Toyama Hamono Seisakusho," refining sharpening and balance techniques. Gaining recognition for high-end shears, he led Sanjo’s shear association during WWII and later pioneered full-scale drop-forged pruning shear production.

Modernization, Expansion & Specialization

Fourth Generation (Toyama Hidehisa & Toyama Hideo - c. mid-20th Century onwards)

In the mid-20th century, the fourth generation modernized production with power presses and automatic grinding, expanding into pruning, bonsai, and ikebana shears. Manufacturing (Toyama Hamono - Hidehisa) and sales (Wakasa-ya Co., Ltd. - Hideo) were separated, while mechanization like NC grinding and laser marking enhanced tradition.

Integration & Global Vision

Fifth Generation (Toyama Hidenobu - 2020 - Present Day)

In February 2020, Hidenobu Toyama unified manufacturing and sales under Toyama Hamono Co., Ltd. for greater efficiency. The company upholds its legacy by blending tradition with innovation, emphasizing global expansion, sustainability, ethical sourcing, and eco-conscious production.

Our Craftsmanship: The Art of Japanese Shears - A Symphony of Skill

Crafting a Toyama Hamono tool requires technical skill and deep steel expertise. Our tools embody traditional Japanese techniques passed down for generations, combined with a relentless drive for improvement.