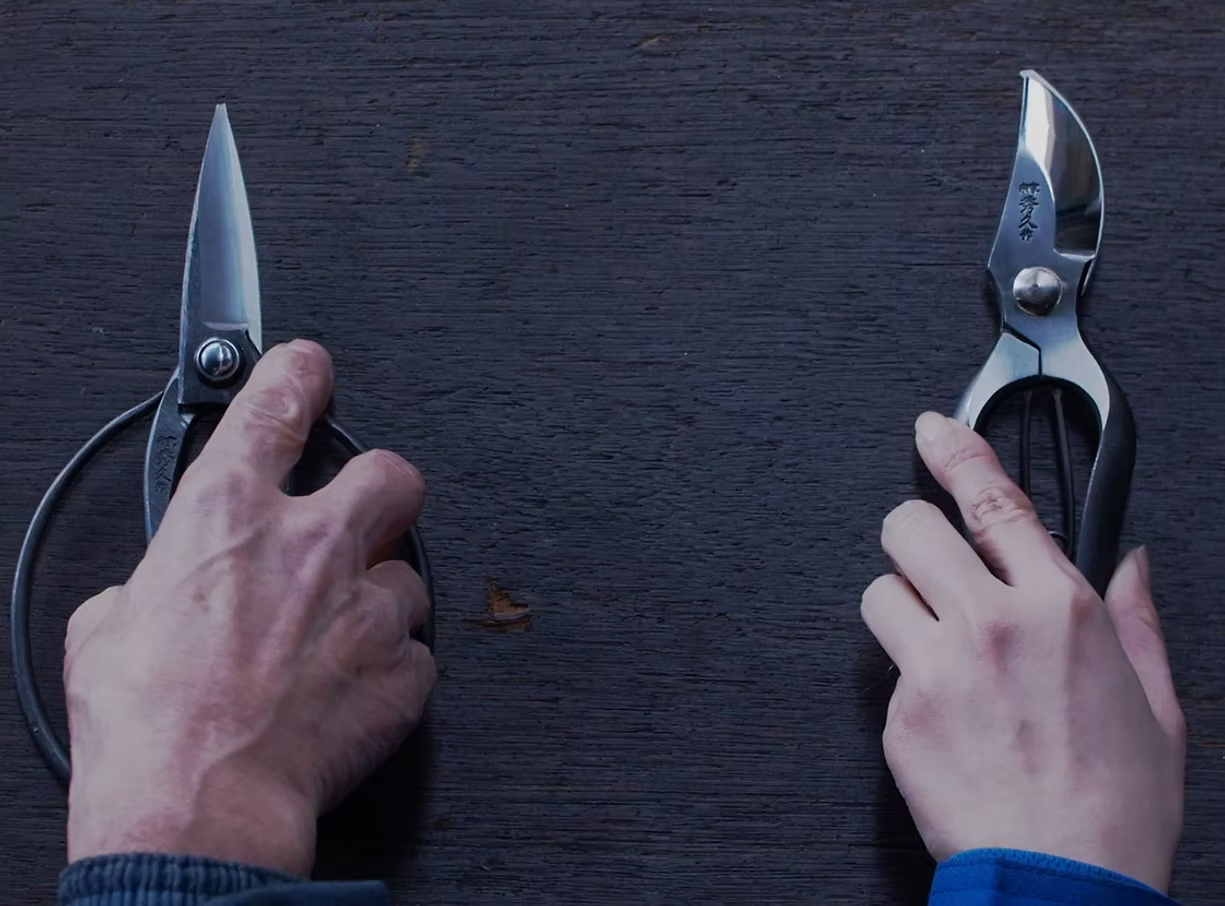

The Art of Japanese Shears

A Symphony of Skill

Crafting a Toyama Hamono tool requires technical skill and deep steel expertise. Our tools embody traditional Japanese techniques passed down for generations, combined with a relentless drive for improvement.

"Hizukuri" Fire Forging

The heart of our craft. Steel is precisely heated and shaped with controlled strikes. This strengthens it for unmatched durability, resilience, and edge retention, connecting to centuries of blacksmithing tradition (katanakaji).

"Ura-togi" Back Hollow Grinding

Gives an exceptionally sharp, clean cut. The back is grinded hollow, reducing friction for smooth cutting. Mastering this skilled process is paramount for sharpness.

"Aiba-tori" Blade Matching & Hand Finishing

Each pair is meticulously hand-assembled and adjusted for perfect alignment, optimal balance, seamless motion, and correct tension. This detail creates a tool feeling like a natural extension of the hand.

"Kinu-tsugi" Silk Finish

A unique process heating steel to specific temperatures with special treatments. Creates distinctive, natural color variation and texture without artificial coloring.